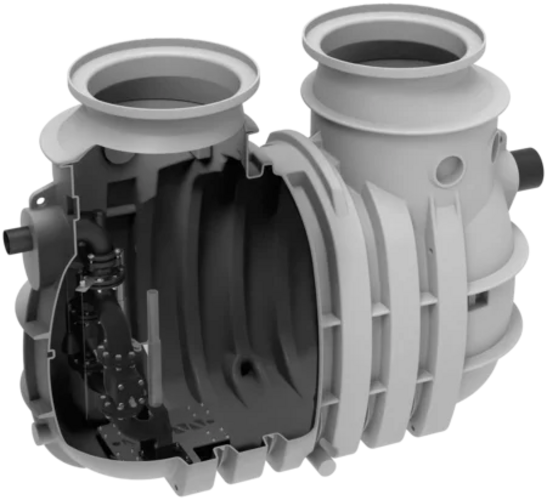

Pumping stations Powerlift-P-H Fix

Product benefits

- Tested in accordance with DIN EN 12050-1

- Suitable for grey and black water (after pumps)

- Automatic underwater coupling with sliding pipe

- Large usable volume up to max.: 1790 litres

- Proven stability of the container: 50 years

- Suitable for

- Grey and black water

- Use behind grease separators

Product information

- Scope

- Commercial and industrial establishments

- Surface water

- Behind separators up to NS20 - in connection with air bubble injection

- Polyethylene tanks

- Below ground installation

- Designed for direct seat of manhole covers

- 2 x maintenance openings ∅ 650 mm for the respective consumption of a necessary cover system (accessories) with load classes B 125 or D 400

- Minimum inlet invert ZT 1040 mm after manhole cover (distance from top edge of ground to lower edge of connection port/pipe bottom)

- Maximum installation depth ET up to approx. 2.25 m (distance from top edge of ground to bottom edge of tank)

- Buoyancy safety of the container: Buoyancy safety up to 1.65 m above the lower edge of the container with extension system and load distribution plate (B 125 and D 400)

- Connections

- Horizontal pipe socket DN 200/ OD 200 mm for inlet line on site

- Horizontal pipe socket DN 100/ OD110 mm for discharge line on site

- 8 x horizontal pipe sockets (closed) DN 100/OD 110 mm for vent stack on site

- Discharge line

- Cast iron backflow preventer, Y-branch pipe and transition elements

- Automatic underwater coupling for the consumption of ACO submerged pumps with DN100 coupling piece

- Level switching

- Optional pressure bell or pressure transducer (both accessories)

- Approved pumping temperature up to 40 °C (max. 65 °C for short periods)

- Pumps, control, covers, evel measuring are not included in the scope of supply and must be ordered separately (see accessories)